Understanding Electroplating Power Supplies

Click: 664 Date: 11/08/2023 5::19::44 PM

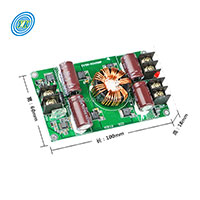

Understanding Electroplating Power SuppliesElectroplating is a process that uses electric current to reduce dissolved metal cations so that they form a metal coating on an electrode. It is an essential process in various industries, such as electronics, jewelry, and automotive. The power supply plays a vital role in this process.The electroplating power supply, also known as a rectifier, converts AC power to DC power, providing the required current and voltage for the electroplating process. These power supplies can be adjusted to deliver the desired current and voltage, allowing for precise control of the electroplating process.There are several types of electroplating power supplies:Switch Mode Power Supplies (SMPS): These are lightweight and compact, offering high efficiency and accuracy. They operate by switching a power transistor between saturation (full-on) and cut off (completely off), minimizing wasted energy.Silicon Controlled Rectifier (SCR): These are more robust and durable, offering high power output. They control power by conducting current in one direction and blocking it in the other.Tap Switch Power Supplies: These are more simplistic and cost-effective. They control power by mechanically connecting different points on a transformer to adjust the voltage.The choice of power supply depends on the specific requirements of the electroplating process, such as the type of metal being plated, the size of the parts, and the desired finish.

Power Distribution Cabinets in Different Usage Scenarios

Click: 882 Date: 11/07/2023 1::59::19 PM

Power Distribution Cabinets in Different Usage ScenariosPower distribution cabinets find applications in a variety of settings, each with unique requirements.Residential Use: In homes, power distribution cabinets, often known as breaker panels, divide the main power supply into smaller circuits for different areas of the house. The cabinets provide a central location where homeowners can control and shut off power to specific areas as needed.Commercial Use: In commercial buildings like offices, malls, and restaurants, power distribution cabinets are larger and more complex to handle the higher power requirements. They may also include additional features like surge protectors to protect sensitive electronics from power surges.Industrial Use: In industrial settings, power distribution cabinets are integral to operations. They are typically larger and more robust, designed to withstand harsh environments and high power loads. These cabinets may also include monitoring systems to track power usage and identify potential issues.Data Centers: In data centers, power distribution cabinets are critical for ensuring consistent and reliable power supply to servers and other IT equipment. These cabinets often feature sophisticated monitoring and management systems for optimal performance.In conclusion, power distribution cabinets play a vital role in various usage scenarios, ensuring safe and efficient power distribution. Their design and features vary depending on the specific requirements of each setting.

The Functionality of Power Distribution Cabinets

Click: 796 Date: 11/07/2023 1::53::25 PM

The Functionality of Power Distribution CabinetsA power distribution cabinet, also known as a distribution board or panelboard, is a crucial component of any electrical system. Its primary function is to divide the power feed into subsidiary circuits, providing a protective fuse or circuit breaker for each circuit in a common enclosure.Power distribution cabinets are designed to ensure safety, efficiency, and reliability in power distribution. Here are some of their key functions:Circuit Distribution: The cabinet distributes the main power supply into smaller circuits to make the power manageable and safe for use in homes, offices, and industries.Protection: Each circuit within the cabinet is protected by a circuit breaker or fuse. This protection mechanism prevents overloading and short circuits, which can lead to fires and other damage.Control: The cabinet provides a control point for all the circuits. Users can manually shut off power to specific circuits for maintenance, repair, or in case of an emergency.Isolation: The power distribution cabinet isolates electrical circuits from the main power supply. This isolation is crucial in preventing electrical shock hazards.

The Use of Electroplating Power Supplies in the Automotive Industry

Click: 792 Date: 11/06/2023 2::10::22 PM

The Use of Electroplating Power Supplies in the Automotive IndustryThe automotive industry is another major user of electroplating power supplies. Here, they are used in the electroplating of various parts of a vehicle, from the body panels to the engine components.One of the key uses of electroplating in the automotive industry is in the production of corrosion-resistant coatings. By electroplating parts with metals like zinc and nickel, manufacturers can significantly enhance the lifespan of these parts. This is crucial in regions with high humidity or salinity, where corrosion can rapidly degrade the parts.In addition, electroplating power supplies are used in the production of decorative coatings. For instance, they are used to plate car emblems and trim pieces with metals like chrome and gold. These coatings not only enhance the aesthetic appeal of the vehicle but also provide a layer of protection against the elements.In conclusion, electroplating power supplies play a vital role in various industries, from electronics manufacturing to automotive production. By providing the necessary voltage and current for the electroplating process, they enable the production of durable, high-quality components.

The Role of Electroplating Power Supplies in Electronics Manufacturing

Click: 661 Date: 11/06/2023 1::55::02 PM

The Role of Electroplating Power Supplies in Electronics ManufacturingElectroplating power supplies play a crucial role in electronics manufacturing. They provide the necessary voltage and current needed for the electroplating process, which involves the deposition of a metal coating onto a conductive surface.This process is widely used in electronics manufacturing to provide a protective coating to various components. For instance, it's used to plate connectors and printed circuit boards (PCBs) with metals like gold and silver. These coatings not only enhance the aesthetic appeal of the components but also improve their conductivity and resistance to corrosion.Moreover, electroplating power supplies ensure the uniformity of the metal coating. By carefully controlling the voltage and current during the electroplating process, these power supplies can ensure that the coating is evenly distributed over the surface of the component. This is crucial for ensuring the optimal performance and longevity of the components

The Composition and Functionality of YUCOO Power Distribution Cabinets

Click: 864 Date: 11/04/2023 09::36::05 AM

The Composition and Functionality of YUCOO Power Distribution CabinetsYUCOO, a reputable manufacturer of power distribution cabinets, offers products that feature a fully enclosed structure with side panels, bottom plates, top plates, and front and rear doors. The structure of the cabinet is designed to ensure operational safety, reliability, and ease of maintenance and inspection.YUCOO's power distribution cabinets are designed to handle the heat, electric arc, impact, vibration, magnetic field, or electric field produced by each electrical component during operation without affecting the normal functioning of other electrical components. The surface of the cabinet is coated with a non-glare layer that is smooth, uniform in color, without flow marks or exposure, and the metal parts are without burrs or rust.In terms of power distribution, YUCOO's cabinets are designed to provide completely independent dual circuit power supply to one or multiple network cabinets. For dual circuit cabinets, each circuit should have a separate neutral line row and they should not be interconnected or shared.One of the key features of YUCOO's power distribution cabinets is the intelligent monitoring system. This system can monitor the switch status and load conditions of the power distribution system. It is capable of monitoring a range of input electrical parameters and output branch electrical parameters. This information allows users to understand the operation of each device, adjust the load distribution in time, and clearly understand the power consumption of each cabinet.In conclusion, power distribution cabinets, like those manufactured by YUCOO, play a crucial role in managing and distributing power supply in data centers and large network rooms. They not only ensure operational safety and reliability but also provide valuable data for energy efficiency management.

The Purpose and Structure of Power Distribution Cabinets in Server Racks

Click: 818 Date: 11/04/2023 09::23::17 AM

The Purpose and Structure of Power Distribution Cabinets in Server RacksA power distribution cabinet, also known as a header cabinet, is a crucial component in data centers, power rooms, telecommunication equipment rooms, and large network rooms. It is designed to distribute and manage power supply to one or multiple server racks within the same room, offering protective functionalities.Companies like YUCOO manufacture power distribution cabinets that ensure operational safety, reliability, and convenience in maintenance. The heat, electric arc, impact, vibration, magnetic field, or electric field produced by each electrical component during operation should not affect the normal functioning of other electrical components.The structure of the power distribution cabinet is fully enclosed, featuring side panels, bottom plates, top plates, and front and rear doors. A well-designed cabinet will have a neat exterior, with all welding spots even, firm, without cracks, residues, noticeable deformation, or burn-through.The power distribution cabinet should provide completely independent dual circuit power supply to one or multiple network cabinets. For dual circuit cabinets, each circuit should have a separate neutral line row and they should not be interconnected or shared.The power distribution cabinet also includes an intelligent monitoring system that can monitor the switch status and load conditions of the power distribution system. The system can monitor various input electrical parameters such as power, active power, reactive power, apparent power, power factor, three-phase voltage, current, frequency, etc., and output branch electrical parameters such as rated current, actual current, load percentage, load current harmonic percentage, load power, power factor, etc. This information enables users to understand the operation of each device, adjust the load distribution in time, and clearly understand the power consumption of each cabinet, providing a reliable basis for energy efficiency management and reducing energy consumption.

The Role of YUCOO’s Electroplating Power Supplies in Various Electroplating Processes

Click: 869 Date: 11/03/2023 1::53::41 PM

The Role of YUCOO's Electroplating Power Supplies in Various Electroplating ProcessesThe electroplating process can vary depending on the type of metal being plated and the desired outcome. Different processes require different types of power supplies, and YUCOO's range of electroplating power supplies caters to these varying needs.Chrome PlatingAmong various types of electroplating processes, chrome plating is significantly influenced by the waveform of the power supply. YUCOO's power supplies with low ripple direct current are ideal for chrome plating, as they help to ensure a wide bright range and prevent issues such as blooming and graying of the plating layer.Bright Acid Copper PlatingFor bright acid copper plating, the ripple factor of the power supply output can greatly impact the brightness and leveling of the plating. YUCOO's power supplies with low ripple factors are beneficial in this process, as they enhance the brightness and leveling of the plating, and also widen the bright current density range.Nickel PlatingBright nickel plating requires a low ripple direct current power supply to ensure the quality of the nickel plating layer and the subsequent chrome plating. YUCOO's power supplies, with their low ripple factors, are well-suited for this application.Tin PlatingFor sulfate-acid tin plating, a power supply with a low ripple factor is necessary to ensure the quality of the plating. YUCOO's power supplies are ideal for this process, providing a low ripple direct current that aids in producing a high-quality tin plating layer.ConclusionThe quality of the power supply in the electroplating process can significantly affect the quality of the final product. With their range of efficient and high-quality power supplies, YUCOO is helping businesses in the electroplating industry achieve better results in their electroplating processes.