News

DC Converters: Technology, Applications, and the Role of YUCOO in the Global Market

Click: 755 Date: 12/06/2023 10::36::24 AM

DC Converters: Technology, Applications, and the Role of YUCOO in the Global Market

Understanding the Various Types of DC Converters: Buck, Boost, Inverting, Non-Inverting, and Linear

DC converters are electronic devices that convert direct current (DC) from one voltage level to another. They are essential in many electronic systems to provide a suitable power supply. Here are some of the most common types of DC converters:

Buck Converter: Also known as a step-down converter, a buck converter reduces the input voltage to a lower level. It is efficient and widely used in power management solutions. The circuit of a buck converter typically includes a diode, an inductor, a switch, and a capacitor.

Boost Converter: Opposite to a buck converter, a boost (step-up) converter increases the input voltage to a higher level. It is useful in applications such as battery-operated devices where the battery voltage needs to be boosted to power certain components.

Inverting Converter: An inverting converter, also known as a negative output converter, changes the polarity of the input voltage. It is often used in operational amplifiers and other analog circuits.

Non-Inverting Converter: A non-inverting converter maintains the same polarity as the input voltage while changing its magnitude. It can function as either a step-up or step-down converter.

Linear DC Converter: Unlike the switched-mode converters mentioned above, a linear DC converter uses linear regulation to provide a stable output voltage. While it offers advantages such as low noise and high precision, it is less efficient and generates more heat.

Each type of DC converter has its own advantages, disadvantages, and preferred applications. The choice of converter depends on the specific requirements of the electronic system.

The Technological Advancements and Efficiency of DC Converters

DC converters have undergone significant technological advancements over the years, leading to improved efficiency, compactness, and reliability. Here's a look at some of the key advancements and the efficiency of DC converters:

Switching Technology: Modern DC converters often use switching technology, specifically in Switched-Mode Power Supply (SMPS) units. This technology involves the rapid switching on and off of the power supply to regulate the output voltage. It results in high efficiency, reduced size, and lighter weight compared to traditional linear regulators.

Digital Control: The advent of digital control in DC converters has enabled finer control over the output voltage and current. This leads to greater stability, improved efficiency, and the ability to respond to changes in input and load conditions more quickly

GaN and SiC Semiconductors: The use of Gallium Nitride (GaN) and Silicon Carbide (SiC) semiconductors in DC converters has improved efficiency and thermal performance. These materials can handle higher voltages and temperatures compared to traditional silicon, resulting in smaller, more efficient converters

Synchronous Rectification: Synchronous rectification is a technique used in DC converters to improve efficiency. It replaces the diode used in traditional converters with a MOSFET, reducing energy losses and improving efficiency

In terms of efficiency, it's important to note that while switching converters like buck, boost, and inverting converters offer high efficiency (often 80-95%), they can generate more noise. On the other hand, linear DC converters, while less efficient (typically 40-70%), generate less noise and provide a cleaner output, making them suitable for sensitive electronic devices. The choice between these converters depends on the specific requirements of the application.

With these advancements, DC converters continue to evolve, providing more efficient and reliable solutions for a wide range of applications.

Designing and Implementing DIY Projects with DC Converters

Designing and implementing DIY projects with DC converters can be a rewarding experience. Whether you're making a portable charger, a solar-powered system, or a custom power supply for a specific device, DC converters are essential components. Below are steps to guide you through the process:

Identify the Requirements: Determine the input and output voltage requirements of your project. This will guide the choice of the DC converter. For example, if you're designing a project that requires stepping up the voltage, a boost converter would be suitable.

Choose the Right DC Converter: Based on your requirements, choose the appropriate DC converter. Consider factors such as efficiency, size, cost, and the manufacturer's reputation

Design the Circuit: Draw a schematic diagram of the circuit, including the DC converter and any other necessary components like capacitors, resistors, and inductors

Assemble the Components: Using a breadboard or a printed circuit board (PCB), assemble the components according to your schematic diagram

Test the Circuit: Test your circuit using a multimeter or oscilloscope to ensure it's working as expected. Make any necessary adjustments to ensure the output voltage and current meet your project's requirements

Implement the Project: Once everything is working correctly, implement the project in its intended setting. This could be installing a DC converter in a solar panel system, an electric vehicle, or a portable power supply

Remember, safety should be your top priority when working with electrical and electronic components. Always double-check your connections and ensure the power is off when making adjustments to the circuit.

With these steps, you can successfully design and implement a DIY project using DC converters. Whether you're a hobbyist or a professional, working with DC converters can be a great way to learn more about electronics and power systems.

Applications of DC Converters in Solar Panels and Electric Vehicles

DC converters play a crucial role in both solar panels and electric vehicles, enabling these systems to operate more efficiently and effectively. Here's how:

Solar Panels:

Maximum Power Point Tracking (MPPT): DC converters are used in MPPT controllers, which are designed to extract the maximum possible power from the solar panels. The voltage output of solar panels varies with light intensity and temperature. An MPPT controller, using a DC-DC converter, adjusts the input voltage to achieve the maximum power output.

Voltage Regulation: Solar panels often produce voltage that is not suitable for direct use or storage (in batteries). DC converters (like buck or boost converters) are used to step down or step up the voltage to the required level

Grid-Tied Systems: In grid-tied solar systems, DC-AC converters (inverters) are used to convert the DC output of the solar panels into AC, which is compatible with the grid and most household appliances.

Electric Vehicles (EVs):

Power Management: DC converters are used in EVs to convert the high voltage from the battery pack to a lower voltage to power the vehicle's electronic systems, such as lights, audio system, and HVAC.

Battery Charging: During regenerative braking, the electric motor acts as a generator and produces electricity. A DC-DC converter is used to step down this voltage to a level suitable for charging the battery

Inverter Input: The traction inverter in an EV, which drives the electric motor, requires a stable DC input. A DC-DC converter ensures that the input to the inverter is maintained at the required level, irrespective of the battery's state of charge.

By enabling efficient power conversion and management, DC converters are essential to the functioning and performance of solar panels and electric vehicles.

Assessing the Global DC Converter Market: Key Players, Pricing, and Reviews

The global DC converter market is a dynamic and competitive industry, with a variety of products catering to various applications such as consumer electronics, automotive, renewable energy, and more. Here's an overview:

Key Players: The market is populated by numerous manufacturers, both established and emerging. Some of the prominent players include Texas Instruments, ON Semiconductor, STMicroelectronics, Infineon Technologies, and YUCOO. YUCOO, with over 20 years of experience in the industry, is known for its high-quality converters and has a strong global presence.

Pricing: The price of DC converters varies significantly based on factors such as power rating, efficiency, type (buck, boost, inverting, non-inverting), and the reputation of the manufacturer. Basic converters can cost a few dollars, while high-power, high-efficiency models can cost several hundred dollars. It's crucial to balance cost with the requirements of the specific application.

Reviews: Reviews are an excellent way to gauge the performance and reliability of DC converters. Customers often share their experiences regarding the converter's efficiency, durability, and customer service of the manufacturer. YUCOO, for instance, has received positive feedback for its range of converters and its commitment to customer satisfaction.

Market Trends: The DC converter market is expected to grow in the coming years, driven by increasing demand for energy-efficient devices, the proliferation of renewable energy, and the growth of electric vehicles. Innovations in converter technology, such as digital power control and advanced semiconductor materials, are also influencing the market dynamics.

When assessing the global DC converter market, it's important to consider these factors and stay informed about the latest trends and developments. This will enable you to make informed decisions, whether you're a buyer, a manufacturer, or an investor in the market.

YUCOO: A Pioneer in the DC Converter Manufacturing Industry

YUCOO is a leading manufacturer in the DC converter industry, renowned for its extensive experience and commitment to quality. Here's an overview of YUCOO's presence in the industry:

Experience and Expertise: With over 20 years of experience, YUCOO has developed a deep understanding of the DC converter market. This expertise allows them to produce high-quality converters that meet the evolving needs of various industries.

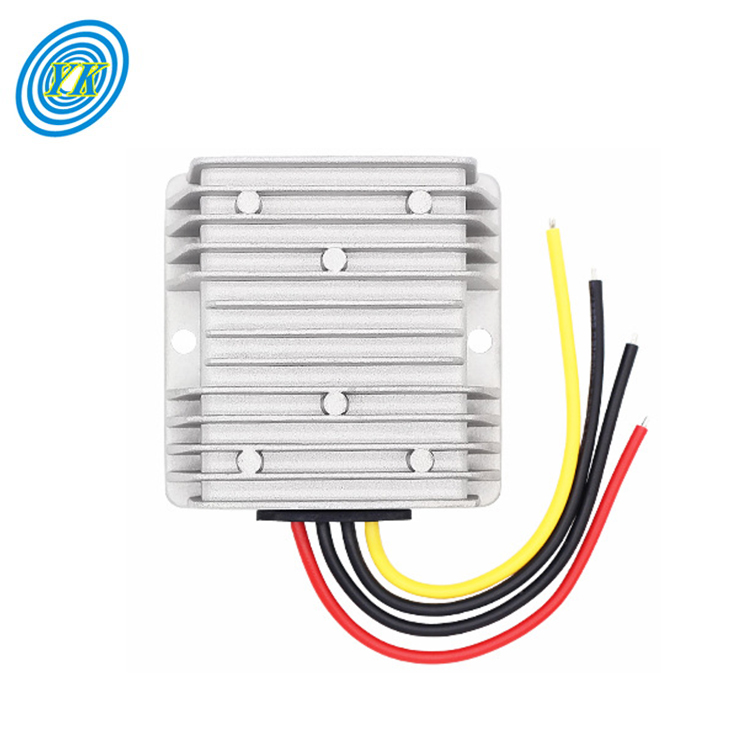

Wide Range of Products: YUCOO offers a wide range of DC converters, including buck, boost, inverting, and non-inverting converters. This diverse product portfolio enables them to serve a broad spectrum of applications, from consumer electronics and automotive systems to renewable energy solutions.

Global Presence: YUCOO's products are sold globally, demonstrating their ability to meet international standards and regulations. Their strong global presence also testifies to their reliable customer service and after-sales support.

Customer Satisfaction: YUCOO has garnered a reputation for delivering high-quality products, which is reflected in the positive reviews from their customers. They are appreciated for their product reliability, efficiency, and the company's commitment to customer satisfaction.

Innovation and Technology: YUCOO continues to innovate in the DC converter industry, integrating the latest technologies to improve the efficiency and performance of their products. They are committed to providing energy-efficient solutions that meet the demands of today's power-hungry devices and systems.

In conclusion, YUCOO is a pioneer in the DC converter manufacturing industry, with a strong commitment to quality, innovation, and customer satisfaction. Their extensive experience and wide range of products make them a reliable choice for DC converter needs.