Click: 820 Date: 08/24/2023 09::21::42 AM

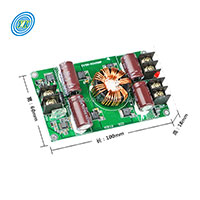

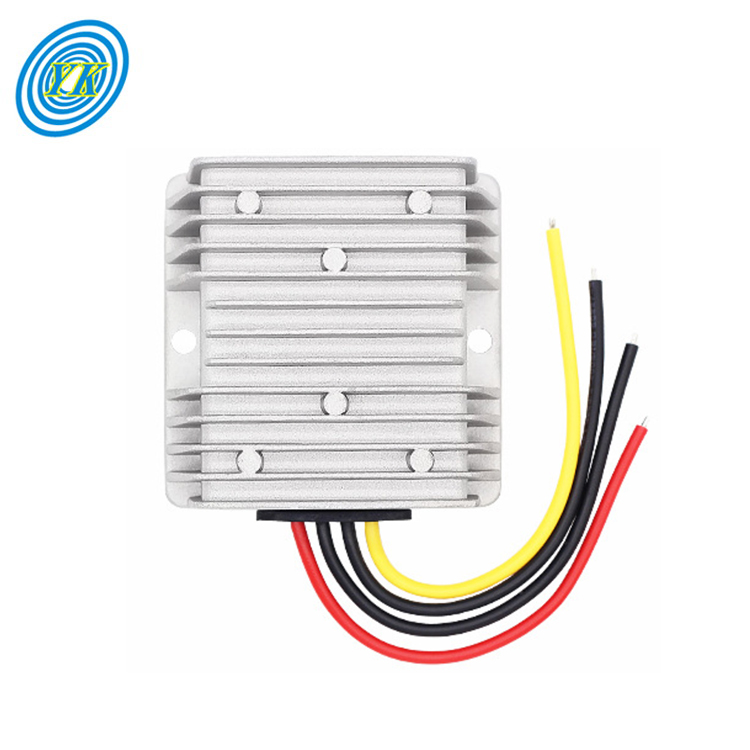

Buck Converter Basics and YUCOO Buck Converter ProductsBuck Converter BasicsA buck converter, also known as a step-down converter, is a DC-to-DC converter circuit that reduces DC voltage. It is widely used in various electronic applications for its energy-efficient design and ability to provide a regulated output voltage lower than the input voltage.The operation of a buck converter is based on the principle of storing energy in an inductor. The voltage drop across the inductor is proportional to the change in the electric current flowing through it. A switching transistor is used to control the on and off states of the circuit, allowing the energy stored in the inductor to be used to produce a continuous output.To ensure safe and efficient electricity usage, it is recommended to use a regulated buck converter. Dedicated buck controller ICs, such as the LM2596, are designed specifically for this purpose and provide reliable regulation.YUCOO Buck Converter ProductsYUCOO, a power supply manufacturer with over 20 years of experience, offers a range of buck converter products that are designed to meet the requirements of various applications. Some of their notable products include:YUCOO High Reliability Buck 12V 24V to 5V 20A DC DC Converter: This buck converter is designed with high reliability and efficiency, making it an ideal solution for various applications. It ensures safe electricity usage by reducing the risk of over-voltage and enhancing power efficiency.YUCOO Aluminum Shell 12/24Vdc to 5Vdc 3A DC DC Buck Converter: This buck converter features an aluminum shell design, providing durability and protection. It converts 12V or 24V input voltage to a stable 5V output, making it suitable for a wide range of applications.YUCOO High-Quality 24Vdc to 12Vdc 5A DC DC Power Step Down Buck Converter: This buck converter is designed to step down a 24V input voltage to a regulated 12V output voltage. It offers high quality and efficiency, ensuring safe and reliable power conversion.YUCOO's buck converter products are known for their high reliability, efficiency, and safety features. They are designed to meet industry standards and provide reliable power conversion solutions for various applications.In conclusion, buck converters, such as the ones offered by YUCOO, are essential components in ensuring safe and efficient electricity usage. Their ability to reduce voltage, regulate output, and provide high efficiency makes them valuable in a wide range of electronic applications. YUCOO's buck converter products, with their focus on reliability and safety, are trusted solutions for power supply needs.

Pure Sine Wave Inverters and Low Frequency Inverters

Click: 1022 Date: 08/16/2023 09::34::26 AM

Pure Sine Wave Inverters: A Game Changer in Power SupplyPure sine wave inverters have emerged as an essential component of any off-grid power system. These inverters convert the Direct Current (DC) from solar panels or battery banks into Alternating Current (AC), which is used by most appliances.YUCOO's pure sine wave inverters stand out for their superior performance and reliability. They are designed to provide a smooth, pure, and high-quality AC output that matches the power from your electricity grid. This ensures all your devices, from sensitive electronics to heavy-duty appliances, can run effectively and efficiently without any risk of damage.Low Frequency Inverters: Long-lasting Backup for Your Home and OfficeLow frequency inverters are another standout product from YUCOO's portfolio. These inverters are designed with a transformer-based system, providing reliable, long-term backup power for your home and office appliances.YUCOO's low frequency inverters are built to last, offering dependable service even in demanding conditions. They come with a variety of features, including bypass and bypass voltage regulation, and the ability to enable generator output. This ensures a steady and uninterrupted power supply, even during power outages.YUCOO: A Commitment to Quality and Customer SatisfactionAt the heart of YUCOO's success is a commitment to customer satisfaction. The company prides itself on delivering top-notch products and services that meet and exceed customer expectations. With a strong technological foundation and innovative production processes, YUCOO has consistently been able to offer high-quality power supply solutions.Furthermore, YUCOO's team of dedicated professionals works tirelessly to ensure that every product is up to the mark. Whether it's a pure sine wave inverter for your off-grid cabin, or a low frequency inverter for your office, you can trust YUCOO to provide a product that delivers in terms of performance, reliability, and longevity.In conclusion, YUCOO's pure sine wave and low frequency inverters represent the future of power supply. With their advanced technology, superior performance, and the backing of a company with a proven track record, they offer a reliable and efficient solution to your power needs. Choose YUCOO, and power your world with confidence.

The Manufacturing Process of Transformers: A Closer Look at Yucoo

Click: 1249 Date: 08/15/2023 4::50::52 PM

The Manufacturing Process of Transformers: A Closer Look at YucooTransformers are an essential component in our modern electrical infrastructure, enabling the efficient transmission and distribution of electrical energy. Yucoo, a leading power supply manufacturer for two decades, has been at the forefront of transformer manufacturing, delivering high-quality and reliable transformers to various industries worldwide.Understanding TransformersA transformer is an electrical device that transfers electrical energy between two or more circuits through electromagnetic induction. Transformers are used to increase (step up) or decrease (step down) AC voltages. They are crucial in power systems, allowing for the long-distance transmission of electricity at high voltages, which is then stepped down for use in residential and commercial environments.Transformer Manufacturing Process at YucooThe transformer manufacturing process at Yucoo is characterized by meticulous attention to detail, strict quality control, and the use of advanced manufacturing techniques and materials.Core AssemblyThe process begins with the assembly of the core. Yucoo uses high-quality silicon steel, known for its excellent magnetic properties, to construct the cores of their transformers. The core pieces are cut precisely and laminated to minimize energy losses due to eddy currents.WindingNext comes the winding process. The conductors, usually made of copper or aluminium, are wound around the core to form the primary and secondary windings. Yucoo ensures tight winding and proper insulation between the windings to prevent short circuits and enhance the transformer's efficiency.InsulationInsulation is a vital part of transformer manufacturing. Yucoo uses high-quality insulating materials to separate the primary and secondary windings and to insulate the windings from the core. This is critical in maintaining the transformer's safety and reliability.TankingFinally, the core and windings are placed into a tank and filled with insulating oil, which acts as a coolant and further enhances electrical insulation. The tank is then sealed to prevent contamination of the oil and internal components.Quality AssuranceYucoo is committed to delivering products of the highest quality. Every transformer undergoes rigorous testing, including tests for winding resistance, insulation resistance, turns ratio, polarity, and core loss, among others. This ensures that every product that leaves the factory meets the highest performance and safety standards.ConclusionYucoo's commitment to quality and innovation has made it a trusted name in the power supply industry. With its meticulous manufacturing process and strict quality control measures, Yucoo continues to deliver transformers that are reliable, efficient, and built to last.

The Manufacturing Process of Telecom Inverters by YUCOO

Click: 815 Date: 08/15/2023 4::04::06 PM

The Manufacturing Process of Telecom Inverters by YUCOOEstablished in 2003, YUCOO has been a leading power supply manufacturer in China for over 20 years, specializing in designing, researching, developing and producing high-frequency switching power supplies, DC/AC power inverters, frequency converters, adjustable power supplies, and battery chargers among others.What is a Telecom Inverter?A telecom inverter is a specific type of power inverter designed to convert direct current (DC) from a battery or solar panel into alternating current (AC) for use in telecom equipment. YUCOO's high frequency telecom inverter is one of their main products, and it's widely used in various fields including China Telecom, China Mobile, China Satellite Communication, as well as Army, Public Security, Irrigation Works, and Highways.Manufacturing Process of Telecom InvertersThe manufacturing process of telecom inverters involves several intricate steps. While the specific details of the manufacturing process are proprietary to YUCOO, the general steps can be outlined as follows:Designing: The process begins with the designing of the telecom inverter. This involves creating detailed blueprints and schematics of the inverter, specifying all the components that will be used and how they will be arranged.Component Sourcing: Once the design is complete, the next step is to source the components that will be used to build the inverter. This includes everything from the circuit board to the transformer and the various electronic components that will be mounted on the board.Assembly: The assembly process involves placing and soldering the components onto the circuit board according to the design schematics. This is typically done using automated machinery for precision and consistency.Testing: After assembly, each inverter is thoroughly tested to ensure it is working correctly. This involves checking the output voltage and frequency, as well as testing the inverter under various load conditions.Quality Control: The final step in the manufacturing process is quality control. This involves a final inspection of each inverter to check for any defects or issues. Only inverters that pass this inspection are approved for sale.YUCOO's manufacturing process stands out for its strong technological strength, exquisite production technology, and advanced and innovative production processes. The company is committed to satisfying customers, intensifying core competence, and progressing with YUCOO's values of faithfully endeavoring, corporate enterprise, pursuing innovation, and going beyond ourselves.ConclusionYUCOO's high-frequency telecom inverters are a testament to the company's dedication to leading technology, reliable quality, satisfactory service, and customer-first approach. The company's products have passed ISO9001 Quality System Certifications and formed a perfect quality management system, earning the trust of many customers with their good quality and services. Whether you are a large telecom operator or a relevant supporting manufacturer, YUCOO can customize any specification power supply as per your request. The company welcomes cooperation to realize win-win strategies together.

Manufacturing Process of Pure Sine Wave Inverter: A Deep Dive into YUCOO’s Expertise

Click: 842 Date: 08/15/2023 3::47::33 PM

Manufacturing Process of Pure Sine Wave Inverter: A Deep Dive into YUCOO’s ExpertiseAs a power supply manufacturer for over 20 years, YUCOO has built a reputation for its high-quality products, including the pure sine wave inverter. This article will provide an overview of the manufacturing process of pure sine wave inverters and how YUCOO has refined this process to deliver superior products to its clients.Understanding the BasicsA power inverter is a device that converts Direct Current (DC) to Alternating Current (AC). Depending on the circuit design, an inverter may produce a square wave, sine wave, modified sine wave, pulsed sine wave, or near-sine pulse-width modulated wave (PWM) .Among these, the sine wave inverter is often preferred as many electrical products are engineered to work best with a sine wave AC power source. The sine wave output is desirable because the standard electric utility provides a sine wave, typically with minor imperfections but sometimes with significant distortion.In the manufacturing of pure sine wave inverters, the focus is on producing a multiple-step sinusoidal AC waveform. This is often marketed as a 'pure sine wave inverter' to distinguish it from inverters with more distortion in their output.YUCOO's Approach to Manufacturing Pure Sine Wave InvertersYUCOO's manufacturing process is underpinned by its operation guideline of 'Leading Technology, Reliable Quality, Satisfactory Service, and Customer First.' The company has passed ISO9001 Quality System Certifications, which is a testament to its commitment to quality management.YUCOO's pure sine wave inverters stand out in the market due to their high-frequency switching power supply. This technology is a key part of YUCOO's product line, which also includes DC/AC power inverters, frequency converters, adjustable power supplies, battery chargers, power distribution units, rectifier systems, and DC-DC converters.The company's pure sine wave inverters are designed to deliver a smooth sine wave output. This results in less choppy outputs compared to square wave and modified sine wave inverters. As a result, YUCOO's pure sine wave inverters are suitable for sensitive electronics devices, medical equipment, smart devices, appliances with AC motors, and other equipment that work best with a sine wave AC power source .Final ThoughtsYUCOO's pure sine wave inverters are a testament to the company's commitment to quality and innovation. With a focus on producing inverters that meet the needs of a wide range of applications, YUCOO continues to be a leader in the power supply manufacturing industry.By delivering products that are not only high in quality but also reliable and efficient, YUCOO is helping to power a diverse range of industries and applications around the world. From telecom operators to supporting manufacturers, the company's power supply products are trusted and used widely.In conclusion, the manufacturing process of pure sine wave inverters involves complex circuit design and careful production to ensure a smooth and pure sine wave output. Companies like YUCOO have mastered this process, delivering high-quality inverters that meet the needs of various applications.

Isolated DC-DC Converter vs Regular Converter: An In-depth Comparison

Click: 113 Date: 08/15/2023 2::52::00 PM

Isolated DC-DC Converter vs Regular Converter: An In-depth ComparisonIn the world of power supply manufacturing, one name stands out prominently - YUCOO. With 20 years of experience, YUCOO has been delivering quality power supply solutions to customers worldwide. In this article, we'll explore one of YUCOO's key offerings - isolated DC-DC converters - and compare them with regular converters.Understanding the BasicsNon-isolated converters, also known as regular converters, and isolated DC-DC converters are two types of power converters. The fundamental difference between them lies in the way they handle electrical isolation.In non-isolated converters, the input and output stages share a common ground, allowing current to flow directly between the two sides. On the other hand, in an isolated converter, the input and output stages have separate grounds, preventing direct current flow between them. This electrical isolation is typically achieved using a transformer.Advantages of Isolated DC-DC ConvertersIsolated converters offer several benefits over regular converters:Safety Compliance: Isolated converters provide a safety barrier that prevents dangerous voltages from becoming present on the output side. This is especially crucial in applications where the equipment is directly connected to the circuit, such as in medical devices.Noise Reduction: Isolated converters can eliminate ground loops, which can be useful in separating a sensitive analog rail from a noisy digital rail. This is beneficial in applications where noise can interfere with the circuit's performance.Level Shifting: Another advantage of isolated converters is the ability to shift or invert the output relative to another point in a circuit, which is not possible with non-isolated converters.Advantages of Regular ConvertersWhile isolated converters provide several benefits, non-isolated converters also have their strengths:Size: Non-isolated converters tend to be smaller than isolated converters, which can be a crucial factor in applications where space is limited.Efficiency: Non-isolated converters generally offer better efficiency and regulation than isolated converters. The absence of an isolation barrier allows for the output to be directly sensed and tightly controlled for better regulation and transient performance.In conclusion, the choice between isolated DC-DC converters and regular converters depends on the specific application requirements. YUCOO, with its extensive experience in power supply manufacturing, offers both types of converters, ensuring that whatever your power supply needs, they can provide a solution that fits.

Powering the Future with YUCOO’s Portable Power Stations

Click: 904 Date: 08/10/2023 4::52::24 PM

Powering the Future with YUCOO's Portable Power StationsAs a renowned power supply manufacturer for over 20 years, YUCOO has consistently provided innovative and reliable power supply solutions. One of our key product lines includes portable power stations, which are designed to offer reliable and efficient power solutions for a variety of applications.Portable power stations are essentially large batteries that can power multiple devices simultaneously. They are versatile, portable, and offer a reliable power source in situations where traditional sources of power are unavailable or inconvenient.At YUCOO, we understand that each user has unique power needs. Therefore, we design our portable power stations to cater to a wide range of devices and applications. Whether you need to power your camping gear, your work tools at a remote site, or your home appliances during a power outage, our portable power stations are equipped to handle your needs.Our portable power stations are designed with user convenience in mind. They are lightweight, compact, and easy to carry. Moreover, they are built with multiple output ports, allowing you to power several devices at once. With these features, YUCOO's portable power stations provide a convenient and efficient power solution wherever you go.In conclusion, YUCOO's portable power stations are a testament to our commitment to providing innovative and reliable power solutions. We continue to strive for excellence in our products and services, ensuring our customers can depend on us for their power supply needs.

The Importance of Transformers in Power Supply Systems

Click: 852 Date: 08/10/2023 4::43::56 PM

The Importance of Transformers in Power Supply SystemsFor two decades, YUCOO has been a trusted manufacturer of power supply solutions. A key product in our range is the transformer, an essential component in virtually all power supply systems.Transformers are electrical devices used to transfer electrical energy between two or more circuits through electromagnetic induction. They are critical in power supply systems as they can increase or decrease the voltage levels according to the needs of the system.At YUCOO, we are dedicated to producing high-quality transformers that offer reliable performance. Our transformers are designed with advanced and innovative production processes, ensuring they deliver optimum performance in various power supply systems.Whether it's for home appliances, industrial machinery, or sophisticated IT equipment, transformers play a vital role in ensuring these devices receive the right voltage level. This not only ensures the smooth operation of these devices but also helps to prevent potential damage caused by voltage fluctuations.In conclusion, transformers are a fundamental part of any power supply system. At YUCOO, we understand this importance and are committed to providing our customers with high-quality transformers that meet their power supply needs.