Click: 845 Date: 08/07/2023 3::20::28 PM

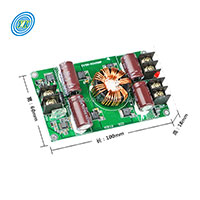

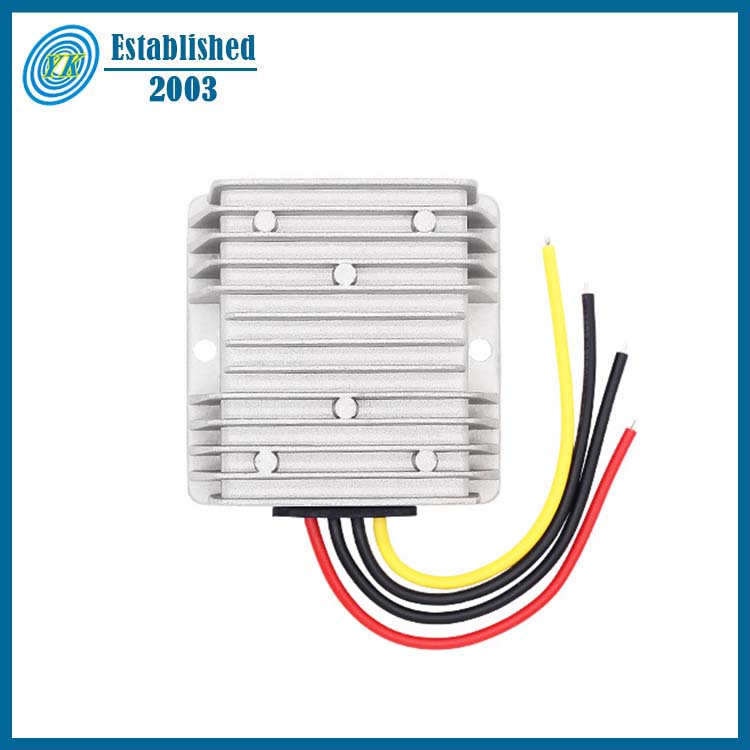

Yucoo is a professional manufacturer that has been producing power supplies for over 20 years. The company, established in 2003, specializes in designing and researching power supply technologies, providing customers with satisfactory products and good services.Yucoo manufactures a wide range of power supply products, including DC-DC converters, power inverters, power distribution units, battery chargers, telecom rectifier systems, switching power supplies, frequency converters, and MPPT controllers. They also offer adjustable power supplies, which are popular among their product line.When it comes to DC converter technology, Yucoo offers a range of products. Their DC-DC converters span a range from 1-500W to 500W-10KW. They also offer different types of DC converters such as Buck DC-DC Converters and Boost DC-DC Converters. This variety allows them to cater to a wide range of customer needs.In terms of the technology behind these products, DC converters, also known as DC to DC converters, are electronic devices that convert a source of direct current (DC) from one voltage level to another. They are important in portable electronic devices such as cellular phones and laptop computers, which are supplied with power from batteries primarily. These converters can increase or decrease the voltage level in accordance to the needs of the device or the battery.Yucoo's DC converters are known for their quality and reliability. One of their notable products is the isolated power supply 24v to 12v step down DC converter module, which is highly sought after in the market.In conclusion, Yucoo's expertise in power supply manufacturing, particularly in DC converter technology, has made them a go-to choice for many customers. Their broad product range, quality, and commitment to customer satisfaction have helped them to build a strong reputation in the power supply industry.

Click: 0 Date: 08/07/2023 3::06::12 PM

Yucoo Network Equipment Co., LTD, established in 2003, specializes in designing and manufacturing high-tech electric products, including various types of inverters such as LCD Display Power Inverter, High Frequency Telecom Inverter, Portable Inverter, Industry Frequency inverter, Low frequency power inverter with charger, and Modified sine wave inverter, among others. It is one of the leading manufacturers in the field of electric drive and control in China, with a strong technological strength and advanced production processes.Inverter technology has a rich history, with its roots going back to the late 19th century. The development of the modern inverter is attributed to the work of Nikola Tesla, who was a pioneer in the development of alternating current (AC) technologies. Tesla's inventions paved the way for the development of the photovoltaic (PV) inverter, a crucial component of any solar power system.The primary function of an inverter in a solar power system is to convert the direct current (DC) generated by the solar panels into alternating current (AC) that can be used by most household appliances. This process is known as inversion. The development of the "non-islanding inverter" by scientists at Sandia Laboratories in Albuquerque, New Mexico, in the year 2000, was a significant step forward in inverter technology. This device could automatically divert or turn off electricity flow from grid-connected PV systems when an electric distribution line shuts down, which was a major safety concern for utility companies.Yucoo, with its expertise in inverter manufacturing, continues to play a significant role in the evolution of inverter technology. It is dedicated to providing high-quality products and services to its customers, and it strives to innovate and improve in the field of electric drive and control. The company's range of inverters caters to a variety of applications, from portable inverters for small-scale use to industrial frequency inverters for larger operations.In conclusion, the history and development of inverter technology is a fascinating journey, with companies like Yucoo contributing significantly to its progress. The role of inverters in our daily lives, particularly in renewable energy systems, is of paramount importance, and the continued innovations in this field promise a more efficient and sustainable future.

Low Frequency Inverters with Built-in Chargers

Click: 1178 Date: 08/01/2023 5::27::06 PM

Low frequency inverters are a type of power inverters that operate at low frequencies, typically around 60 Hz. They are distinguished from high frequency inverters by the size of their transformers and the switching speed of their transistors.These inverters are designed to convert DC power (Direct Current) into AC power (Alternating Current), which is used to run household items and electrical appliances. This makes them an essential component for anyone without access to a mains power source, as they can provide a plentiful amount of electricity.Advantages of Low Frequency InvertersLow frequency inverters have several advantages over their high frequency counterparts. They are designed to handle higher power spikes for longer periods, making them more robust and reliable. This capability is particularly important for devices like power tools, pumps, and appliances with electric motors that require high starting power. Low-frequency inverters can operate at peak power levels up to 300% of their nominal power level for several seconds, whereas high-frequency inverters can only operate at 200% power level for a fraction of a second.Another advantage is their reliability. Low-frequency inverters operate using powerful transformers, which are more reliable and sturdy than the high-frequency inverter’s MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors), which use electronic switching and are more prone to damage, particularly at high power levels.Built-in Charger and Other FeaturesIn addition to their robustness and reliability, low-frequency inverters come with a wide range of technical features and capabilities, including a built-in battery charger. This feature allows the inverter to charge a battery from an AC power source, such as a generator or shore power at an RV park, truck stop, or home.Other features of low-frequency inverters include UPS (Uninterruptible Power Supply) functions, bypass mode with no battery connected, power saving mode, and various charge settings for different battery types and charging voltages.Applications of Low Frequency InvertersLow frequency inverters are designed for large off-grid power systems and are more suitably equipped for powering heavy appliances. They are typically used in power levels within the thousands, such as 2000W-3000W and above. They are ideal for powering various kitchen appliances, such as refrigerators, microwaves, dishwashers, ovens, and devices with electric motors like power tools, washing machines, vacuum cleaners, and air conditioners.Despite their larger size and weight compared to high-frequency inverters, low-frequency inverters are a great investment for anyone with a lot of powerful electrical appliances in places with limited or no access to standard electricity. They can provide a reliable backup power solution and even completely replace conventional electricity with the same quality power supply.

Click: 1230 Date: 07/31/2023 09::58::20 AM

Frequency ConverterA frequency converter, also known as a frequency changer, is a device that converts the frequency of an alternating current (AC) from one value to another. Besides changing the frequency, these devices may also alter the voltage, but this can be considered incidental to their primary function. Voltage conversion of AC is much simpler to achieve than frequency conversion.Types of Frequency ConvertersFrequency converters can be broadly classified into static, rotating, and combined types.Static Frequency Converters: These can be further subdivided into electromagnetic and rectifier types. Electromagnetic frequency converters are based on changing the shape of a sinusoidal alternating voltage using magnetic nonlinear elements, such as chokes and transformers with saturable cores. They are often used as frequency dividers and multipliers . Rectifier-type converters often employ transistors and thyristors as rectifiers, and are primarily used in radio-engineering equipment. Their power rating can be as high as 2 to 3 kilovolt-amperes (kVA).Rotating Frequency Converters: These converters can be built either as two machines or as one machine. The two-machine type usually combines an electric driving motor and a generator of alternating or direct current. Their efficiency can reach 85 percent, and their power ratings range from 30 to 800 kVA.Applications of Frequency ConvertersFrequency converters find usage in various applications, including:Power Grids: They are used for converting bulk AC power from one frequency to another when two adjacent power grids operate at different utility frequencies.Variable-Frequency Drives: A variable-frequency drive (VFD) is a type of frequency changer used for speed control of AC motors. The speed of a synchronous AC motor is dependent on the frequency of the AC power supply. Therefore, changing frequency allows the motor speed to be varied.Aerospace and Airlines Industries: Often airplanes use 400 Hz power, so a 50 Hz or 60 Hz to 400 Hz frequency converter is needed for use in the ground power unit used to power the airplane while it is on the ground.Renewable Energy Systems: In renewable energy systems, frequency converters are an essential component of doubly fed induction generators (DFIGs) as used in modern multi-megawatt class wind turbines.Frequency Converter TechnologyThere are two basic types of Frequency Converters: Rotary Frequency Converters and Solid State (Static) Frequency Converters. Rotary Frequency Converters use electrical energy to drive a motor. On the other hand, Solid-state frequency converters take the incoming AC and convert it to direct current (DC).A Rotary Frequency Converter is manufactured with the use of a Motor Generator and a Solid State (Static) Frequency Converter is manufactured with the use of semiconductors and power stages. The Rotary machine is brute force as opposed to the Static machine.In conclusion, frequency converters are crucial devices in various industries due to their ability to convert the frequency of an alternating current. They are particularly important in applications that require the control of motor speed, synchronization of different power grids, and in the operation of specific equipment in the aerospace industry.

Click: 1123 Date: 07/29/2023 2::39::29 PM

Adjustable DC Power SupplyAn adjustable DC power supply, also known as a variable DC power supply, is an essential tool in the fields of electronics testing, design, and manufacturing. It provides a source of power with an output voltage that can be varied according to the user's needs. This flexibility allows for the testing of a variety of devices under different voltage and current conditions, making adjustable DC power supplies indispensable in a wide range of applications.What is an Adjustable DC Power Supply?An adjustable DC power supply is a power source with an output voltage that can be varied by the user. They are used extensively in electronic labs for testing and powering devices. These power supplies provide different voltage levels and current outputs, which are critical for testing various electronic components and systems.Key CharacteristicsWhen selecting an adjustable DC power supply, there are several key characteristics to consider:Available Power: The power output that the supply can provide is an important factor in your selection. This depends on the voltage and current that your device under test (DUT) requires.Noise Requirements: The noise produced by the power supply can affect the performance of sensitive circuits. Therefore, choosing a power supply with low noise is crucial.Programming Accuracy: The ability to accurately set the output voltage and current is another key characteristic. High precision and stability are desirable for accurate testing and measurements.Software Availability: Some power supplies come with software that allows you to automate tests and analyze data.Types of Adjustable DC Power SupplyAdjustable DC power supplies come in two main types: linear and switching.Linear Power Supplies: They operate by transforming the input voltage to the desired level and then regulating it to produce a stable output. Linear power supplies are known for their low noise output and good regulation but are less efficient and generate more heat.Switching Power Supplies: They convert the input voltage to the desired level using a high-frequency switching transistor. Switching power supplies are more efficient and compact but can generate more noise.Applications of Adjustable DC Power SupplyAdjustable DC power supplies have a wide range of applications, including:Education: They are used in electrical engineering education for practical learning and experiments.Research and Development: Adjustable DC power supplies are used in research labs for powering and testing new designs.Manufacturing: They are used in manufacturing for quality control and end-of-line testing.DIY Projects: Hobbyists and DIY makers use adjustable DC power supplies for making and testing circuits.ConclusionAn adjustable DC power supply is a vital tool for anyone involved in electronics. Whether you are a student, researcher, engineer, or hobbyist, the ability to provide a variable source of power to your projects is invaluable. When selecting a power supply, consider the power output, noise requirements, programming accuracy, and available software. Remember, more power and features do not necessarily make a better power supply – it's about how you use it.

Emerging Trends in Switching Power Supply Design: Towards Higher Efficiency and Compactness

Click: 1744 Date: 07/17/2023 5::06::39 PM

Switching power supplies are widely used in electronic devices to efficiently convert electrical power from one voltage level to another. As technology advances, there are several emerging trends in switching power supply design that are focused on achieving higher efficiency and compactness. These trends aim to address the growing demand for more energy-efficient devices and the need to reduce the size and weight of power supplies. Wide Bandgap (WBG) Semiconductors: Wide bandgap semiconductors, such as silicon carbide (SiC) and gallium nitride (GaN), are gaining popularity in switching power supply design. These materials offer higher breakdown voltage, faster switching speeds, and lower conduction and switching losses compared to traditional silicon-based devices. WBG semiconductors enable higher power density, greater efficiency, and reduced system size. Digital Control and Advanced Control Techniques: Digital control techniques, such as digital pulse-width modulation (PWM) controllers, provide more precise and flexible control of the power supply. They offer improved dynamic response, better stability, and increased efficiency. Advanced control techniques like predictive control and adaptive control algorithms are also being employed to optimize power supply performance under different load conditions. Topology Innovations: New power supply topologies are being developed to improve efficiency and reduce size. These include resonant converters, LLC (inductance-inductance-capacitance) converters, and switched-capacitor converters. Resonant converters minimize switching losses, LLC converters enable high-frequency operation, and switched-capacitor converters provide higher power density and reduced size. Modular Designs and Integrated Solutions: Modular power supply designs offer scalability, flexibility, and ease of maintenance. They allow for easy expansion or replacement of power modules and provide higher reliability in multi-output applications. Integrated solutions, such as system-in-package (SiP) and power system-in-package (PSiP), combine power supply components into a single package, reducing footprint and improving thermal management. Energy Harvesting and Power Management Integration: With the increasing popularity of energy harvesting techniques, such as solar, wind, and vibration energy, power supplies are being designed to integrate these energy sources. Power management ICs enable efficient energy harvesting and seamless integration with traditional power sources. This trend promotes energy efficiency and sustainability in various applications. Advanced Thermal Management: Efficient thermal management is crucial in power supply design, especially for high-power applications. Advanced cooling techniques, such as liquid cooling, heat pipes, and multi-layer PCBs, are being employed to dissipate heat effectively. Thermal simulations and optimization algorithms help in designing compact power supplies with improved thermal performance. Overall, the emerging trends in switching power supply design are driven by the need for higher efficiency, improved power density, and compactness. These advancements contribute to the development of more energy-efficient electronic devices, reduce environmental impact, and enhance overall system performance.

AC to DC Converter: Energy Efficiency and Utilization

Click: 1623 Date: 07/14/2023 3::45::10 PM

Introduction: In today's world, where electricity powers almost every aspect of our lives, the efficient conversion of alternating current (AC) to direct current (DC) is crucial. AC to DC converters play a vital role in various electronic devices, ensuring they receive the appropriate power supply. In this blog post, we will explore the significance of AC to DC converters, their energy efficiency, and the advancements in their manufacturing processes. Understanding AC to DC Conversion: AC power, supplied by utility grids, oscillates between positive and negative voltages. However, many electronic devices require a steady and constant flow of power, which is provided by DC. AC to DC converters bridge this gap by converting the fluctuating AC voltage into a stable DC voltage suitable for electronic devices. Energy Efficiency in AC to DC Conversion: Efficiency is a critical factor when it comes to AC to DC conversion. Higher efficiency means less energy loss during the conversion process, resulting in reduced energy consumption and lower operating costs. Modern AC to DC converters employ advanced technologies such as switching mode power supplies (SMPS) to achieve high efficiency levels. SMPS uses semiconductor switches to rapidly switch the input voltage, minimizing energy losses and improving overall efficiency. Power Factor Correction (PFC): Power Factor Correction is another important aspect of AC to DC conversion. It refers to the optimization of the power flow between the AC source and the converter. Traditional AC to DC converters often exhibit poor power factor, leading to reactive power consumption and increased strain on the power grid. PFC techniques, such as active PFC or passive PFC, are employed to improve power factor, reduce harmonic distortion, and enhance energy efficiency. Advancements in Manufacturing Processes: The manufacturing processes of AC to DC converters have witnessed significant advancements in recent years. These advancements focus on improving energy efficiency, reducing size and weight, and enhancing reliability. Some notable developments include: a. Miniaturization: Through the use of advanced semiconductor materials and packaging techniques, AC to DC converters have become smaller and more compact. This miniaturization enables their integration into space-constrained electronic devices without compromising performance. b. Thermal Management: Efficient heat dissipation is crucial for the reliable operation of AC to DC converters. New manufacturing processes incorporate innovative thermal management techniques such as heat sinks, fans, and advanced materials to ensure optimal temperature regulation and prevent overheating. c. Intelligent Control: The integration of intelligent control systems allows AC to DC converters to adapt to varying load conditions and optimize energy consumption accordingly. These control systems employ algorithms and sensors to monitor and adjust the converter's output, maximizing efficiency and reducing wasted energy. Conclusion: AC to DC converters play a vital role in our modern electronic world, enabling the efficient conversion of power from AC to DC. With advancements in energy efficiency and manufacturing processes, these converters are becoming more reliable, compact, and environmentally friendly. As technology continues to evolve, we can expect further improvements in AC to DC conversion, leading to reduced energy consumption, lower costs, and a greener future.

Unleashing the Potential of DC Converters: Empowering Energy Efficiency

Click: 1228 Date: 07/06/2023 5::03::28 PM

Introduction:Welcome to our blog, where we explore the fascinating world of DC converters and their transformative impact on energy efficiency. In this article, we will delve into the workings of DC converters, their applications, and the benefits they offer in our pursuit of a sustainable future.Understanding DC Converters:DC converters, also known as direct current converters, are electronic devices that convert direct current (DC) into other forms of DC power. They play a crucial role in various applications, including renewable energy systems, electric vehicles, and industrial processes. DC converters enable efficient power transmission and utilization, ensuring optimal energy conversion.Renewable Energy Integration:DC converters are instrumental in integrating renewable energy sources, such as solar and wind power, into our energy systems. They convert the DC output from solar panels or wind turbines into the appropriate voltage and current levels for use in homes, businesses, and industries. This seamless integration promotes the adoption of clean and sustainable energy solutions, reducing our reliance on fossil fuels and mitigating environmental impact.Energy Efficiency and Power Optimization:DC converters contribute to energy efficiency by minimizing power losses during transmission and conversion. Unlike alternating current (AC), which experiences losses during transmission, DC power can be transmitted over longer distances with minimal losses. DC converters ensure efficient power transmission, reducing energy wastage and optimizing power utilization in various applications.Electric Vehicle Charging:DC converters play a vital role in electric vehicle (EV) charging infrastructure. They convert the AC power from charging stations into the DC power required to charge EV batteries. DC fast chargers, equipped with high-power DC converters, enable rapid charging, reducing charging times and enhancing the convenience of EV ownership. This paves the way for widespread adoption of electric vehicles and a greener transportation sector.Industrial Applications:DC converters find applications in various industrial processes, where precise control and efficient power conversion are essential. They enable the conversion of power for motors, control systems, and other industrial equipment, ensuring optimal performance and energy efficiency. DC converters also facilitate the integration of renewable energy sources into industrial operations, reducing reliance on traditional power sources and promoting sustainability.Conclusion:DC converters are key players in our journey towards energy efficiency and sustainability. Their ability to convert and optimize DC power for various applications, including renewable energy integration and electric vehicle charging, is transforming the way we harness and utilize energy. As we continue to embrace clean energy solutions, DC converters will play a pivotal role in maximizing energy efficiency, reducing environmental impact, and shaping a greener future. Let's harness the potential of DC converters and pave the way for a more sustainable and efficient energy landscape.